Monitoring: AI Software for Machine Tools

Neural network technology learns optimum machine behaviour, contributing to maintain the expected production standards: here is the new artificial intelligence software from NUM, developed for condition monitoring of CNC machine tools

The new artificial intelligence software launched by NUM provides CNC machine tool users with highly cost-effective condition monitoring capabilities. Compatible with all of NUM’s latest-generation Flexium+ CNC systems, the NUMai software package is a complete, fully integrated solution for CNC machine tools – it does not require any additional sensors, and runs on the same industrial PC as the CNC system’s HMI.

The collected data is used to teach a neural network

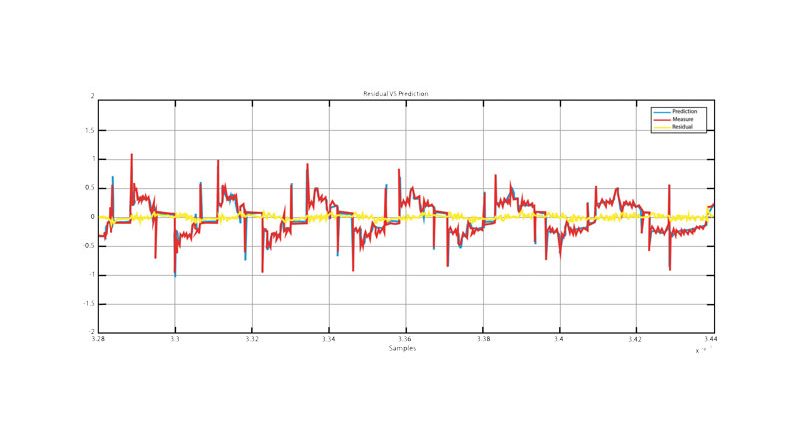

NUMai software can be utilised as soon as a machine tool has been commissioned and is ready to start production, or on a machine that is already being employed. The software initially acquires all pertinent operating data over a period of time, typically some hours, while the machine is being used for normal production tasks. Ideally, a diversity of part programs is run, involving a variety of different machining conditions, in order to ensure that the data is as comprehensive and reliable as possible. The collected data is used to teach a neural network so that any deviation from the “good machine behaviour” and performance can then be detected and predicted; a suitable PC program for subsequent online performance monitoring and diagnostic purposes is generated automatically. During the software’s development, NUM beta tested the technology on a CNC milling machine equipped with three axes and a spindle, which required a neural network comprising 36 neurons with three hidden layers. In this particular instance, 396 parameters needed their values to be accurately defined; this required the acquisition of more than 2 million “known good” data points and 300 iterations of the teaching phase, which took about four hours per axis.

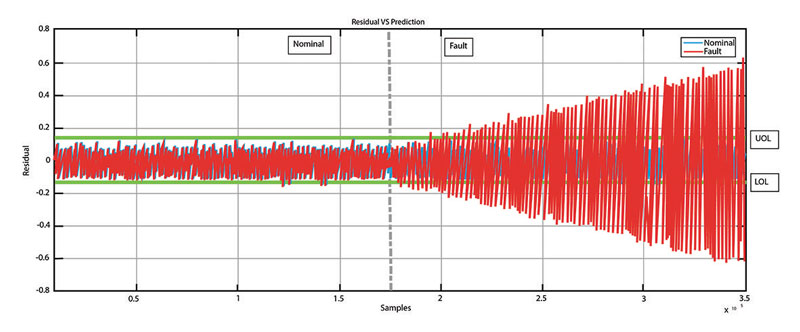

Any discrepancy or deviation is notified to the PLC

NUMai condition monitoring software capitalises on the inherent flexibility of NUM’s Flexium+ CNC platform. As standard, every Flexium+ CNC system includes: a PC which can handle data from the servo drives’ measurement points, a PLC that has direct access to machine parameters, and an NCK oscilloscope feature capable of reading values in real-time. All system communications are handled by FXServer, using fast real-time Ethernet (RTE) networking. During everyday use in the production environment, NUMai software runs in the background on the industrial PC that forms part of the machine tool’s CNC system, continuously monitoring and evaluating the machine’s performance. Any discrepancy or deviation beyond user-defined thresholds is notified to the PLC, which decides what action should be taken – from a simple advisory message to an emergency disengagement. The new NUMai condition monitoring software option can be installed and used on any Flexium+ CNC system running NUM’s Flexium software version 4.1.10.10 or higher.