Vision: Zero Tolerance in the Bakery

The Keyence vision system has been chosen to guarantee the perfection of every single bread roll produced by a multinational bakery company operating in Italy: a 21 Megapixel resolution allows to capture the images of the baking sheet every 2 seconds

In the food sector, the supply chain today does not admit any imperfections. Every product must be perfect from both an organoleptic and aesthetic standpoint. This results in strict quality control on the production line, applied to every single product, without exception.

“Today’s industry typically requires control over 100% of production. From the automotive industry to the chemical and food sectors, the traditional approach of sample testing is no longer considered sufficient,” said Silvano Giberti, owner of Essegi, an Emilia-based system integrator specializing in stand-alone and in-line integrated test benches, as well as special applications for various product areas characterized by quality production in large series. “The evolution of supply chains requires that, for example, if 2 million pieces are produced for a customer, all and none excluded will be delivered without defects and perfectly meeting the functional and aesthetic specifications agreed upon. In order for quality control of 100% of products or semi-finished products to be economically viable, the most advanced technologies must be used”.

Images of the 700×600 mm tray are captured every 2 s.

It is also possible to directly obtain the spatial coordinates of imperfect bread rolls.

The bread rolls are organized in baking sheets holding 30 rolls in a matrix of 5 rows by 6 columns.

An automatic line which produces over 500,000 bread rolls a day

An example of how advanced technological solutions make it possible to meet this challenge successfully is a production line recently automated by Essegi. The customer is one of the main bakery multinationals operating in Italy, in turn supplier of one of the most famous fast food chains in the world.

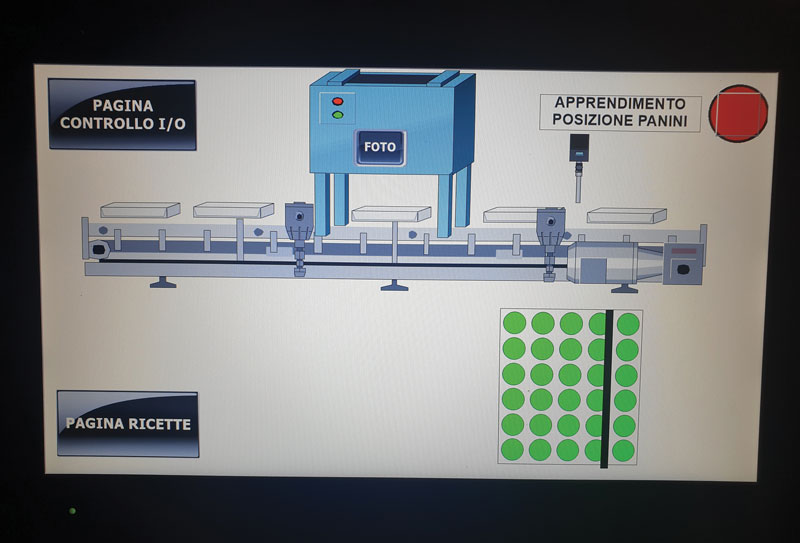

Giberti explained: “In this specific case we dealt with an automatic line which operates 24 hours a day to churn out over 500,000 bread rolls during the day. Organized in baking sheets containing the unleavened dough of 30 bread rolls in a matrix of 5 rows by 6 columns, the rolls enter the hot rooms for leavening. Inside the leavening oven, some micro-corpuscle of black soot from the burning residue could settle on the sandwiches; although it is harmless, it would not be perceived positively by the consumer. Therefore, any sandwiches which are not perfectly white after leavening should be discarded. Our solution is able to identify with absolute certainty, and respecting the high production rates of this line, even the smallest imperfections of only 2 tenths of a millimetre (0.178 mm/pix) on the surface of the sandwich. To achieve this, we used the Keyence XG-X2700 vision system, which allowed us to use a very high resolution camera.

Images captured every 2 seconds

The Keyence vision system allows to capture every 2 s the images of the 30 bread roll baking sheet, measuring 700 by 600 mm, using a resolution of 21 Megapixels. It processes in real time the images in search of defects, generating as a result the value of the X, Y coordinates of the position of the defective bread rolls inside the pan. The vision system, interfaced with the line control system, allows the latter to control air blower nozzles located in the next station. The nozzles visibly deform the imperfect bread rolls, facilitating their subsequent rejection at the end of their path inside the baking oven. To ensure the identification of such small defects within such a large baking pan, and at the required rate, a particularly powerful vision system such as Keyence’s XG-X2700 was required. As Giberti pointed out, the solution chosen and Keyence’s valuable collaboration made it possible not only to satisfy these requirements, but also to directly obtain the spatial coordinates of the imperfect buns. It is a result which Essegi is proud of, and which has made it possible to solve the customer’s productivity and quality control requirements in a creative and technologically advanced way. The company was therefore able to enhance its expertise accrued in the field of electrical, mechanical and software design.